Step aside hard, rigid materials. There is a new soft, sustainable electroactive material in town — and it’s poised to open new possibilities for medical devices, wearable technology and human-computer interfaces.

Using peptides and a snippet of the large molecules in plastics, Northwestern University materials scientists have developed materials made of tiny, flexible nano-sized ribbons that can be charged just like a battery to store energy or record digital information. Highly energy efficient, biocompatible and made from sustainable materials, the systems could give rise to new types of ultralight electronic devices while reducing the environmental impact of electronic manufacturing and disposal.

With further development, the new soft materials could be used in low-power, energy-efficient microscopic memory chips, sensors and energy storage units. Researchers also could integrate them into woven fibers to create smart fabrics or sticker-like medical implants. In today’s wearable devices, electronics are clunkily strapped to the body with a wristband. But, with the new materials, the wristband itself could have electronic activity.

“This is a wholly new concept in materials science and soft materials research,” said Northwestern’s Samuel I. Stupp, who led the study. “We imagine a future where you could wear a shirt with air conditioning built into it or rely on soft bioactive implants that feel like tissues and are activated wirelessly to improve heart or brain function.

“Those uses require electrical and biological signals, but we cannot build those applications with classic electroactive materials. It’s not practical to put hard materials into our organs or in shirts that people can wear. We need to bring electrical signals into the world of soft materials. That is exactly what we have done in this study.”

Stupp is the Board of Trustees Professor of Materials Science and Engineering, Chemistry, Medicine and Biomedical Engineering at Northwestern. He also has served over the past decade as director of the U.S. Department of Energy-supported Center for Bio-Inspired Energy Science, where this research began. Stupp has appointments in the McCormick School of Engineering, Weinberg College of Arts and Sciences and Northwestern University Feinberg School of Medicine. Yang Yang, a research associate in Stupp’s laboratory, is the paper’s first author.

Peptides meet plastics for true innovation

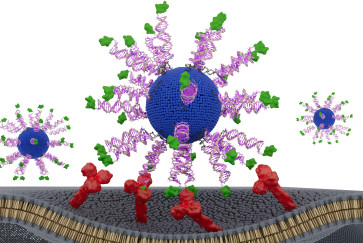

The secret behind the new material is peptide amphiphiles, a versatile platform of molecules previously developed in Stupp’s laboratory. These self-assembling structures form filaments in water and have already demonstrated promise in regenerative medicine. The molecules contain peptides and a lipid segment, which drives the molecular self-assembly when placed in water.

In the new study, published in the journal Nature, the team replaced the lipid tail with a miniature molecular segment of a plastic called polyvinylidene fluoride (PVDF). But they kept the peptide segment, which contains sequences of amino acids. Commonly used in audio and sonar technologies, PVDF is a plastic with unusual electrical properties. It can generate electrical signals when pressed or squeezed — a property known as piezoelectricity. It also is a ferroelectric material, which means it has a polar structure that can switch orientation by 180 degrees using an external voltage. The dominant ferroelectrics in technology are hard materials and often include rare or toxic metals, such as lead and niobium.

Today’s wearables are clunkily strapped to the body with a wristband. But with the new materials, the wristband itself could have electronic activity.

“PVDF was discovered in the late 1960s and is the first known plastic with ferroelectric properties,” Stupp said. “It has all the robustness of plastic while being useful for electrical devices. That makes it a very high-value material for advanced technologies. However, in pure form, its ferroelectric character is not stable, and, if heated above the so-called Curie temperature, it loses its polarity irreversibly.”

All plastics, including PVDF, contain polymers, which are giant molecules typically composed of thousands of chemical structural units. In the new study, the Stupp laboratory precisely synthesized miniature polymers with only three to seven vinylidene fluoride units. Interestingly, the miniature segments with four, five or six units are programmed by nature’s beta-sheet structures, which are present in proteins, to organize into a stable ferroelectric phase.

“It was not a trivial task,” Stupp said. “The combination of two unlikely partners — peptides and plastics — led to a breakthrough in many respects.”

Not only were the new materials equally ferroelectric and piezoelectric as PVDF, but the electroactive forms were stable, with the ability to switch polarity using extremely low external voltages. This opens the door for low-power electronics and sustainable nanoscale devices. The scientists also envision developing new biomedical technologies by attaching bioactive signals to the peptide segments, a strategy already used in Stupp’s regenerative medicine research. This offers the unique combination of electrically active materials that are also bioactive.

Just add water

To create the sustainable structures, Stupp’s team simply added water to trigger the self-assembly process. After dunking the materials, Stupp was amazed to find that they achieved the highly sought-after ferroelectric properties of PVDF.

In the presence of an external electric field, ferroelectric materials flip their polar orientation — similar to how a magnet can be flipped from north to south and back again. This property is a key ingredient for devices that store information, an important feature for artificial intelligence technologies. Surprisingly, the investigators found that “mutations” in the peptide sequence could tune properties related to ferroelectricity or even transform the structures into materials that are ideal for actuation or energy storage known as “relaxor phases.”

“Peptide sequence mutations in biology are the source of pathologies or biological advantages,” Stupp said. “In the new materials, we mutate peptides to tune their properties for the physical world.

“Using nanoscale electrodes, we could potentially expose an astronomical number of self-assembling structures to electric fields. We could flip their polarity with a low voltage , so one serves as a ‘one,’ and the opposite orientation serves as a ‘zero.’ This forms binary code for information storage. Adding to their versatility, and in great contrast to common ferroelectrics, the new materials are ‘multiaxial’ — meaning they can generate polarity in multiple directions around a circle rather than one or two specific directions.”

Record-breaking low power

To flip their polarity, even soft ferroelectric materials like PVDF or other polymers typically require a substantial external electric field. The new structures, however, require incredibly low voltage.

“The energy required to flip their poles is the lowest ever reported for multiaxial soft ferroelectrics,” Stupp said. “You can imagine how much energy this will save in increasingly energy-hungry times.”

The new materials also have innate environmental benefits. Unlike typical plastics, which linger in the environment for centuries, the Stupp laboratory’s materials could be biodegraded or reused without the use of harmful, toxic solvents or high-energy processes.

“We are now considering the use of the new structures in non-conventional applications for ferroelectrics, which include biomedical devices and implants as well as catalytic processes important in renewable energy,” Stupp said. “Given the use of peptides in the new materials, they lend themselves to functionalization with biological signals. We are very excited about these new directions.”

The study was supported by the U.S. Department of Energy.