Northwestern researchers have developed a specialized sponge that slurps up pollutants, offering a reusable and cost-effective solution to water contamination.

The big picture: As more waterways contend with algae blooms and pollution caused by minerals from agricultural runoff and industrial manufacturing processes, new methods to remove pollutants like phosphate, copper and zinc are emerging across fields. While solutions exist, they tend to be costly and can be used just once.

How it works: The sponge, coated with nanoparticles that have an affinity for pollutants, can collect metals like zinc and copper, as well as phosphate, and in previous iterations has successfully pulled lead from water, and microplastics and oil from lakes and oceans. It then releases these valuable resources when it is exposed to different pH’s.

Built for Chicago

In the study, researchers define a method to tailor their platform to specific Chicago pollutants and then selectively release them, giving resources that typically must be mined a potential for a second life.

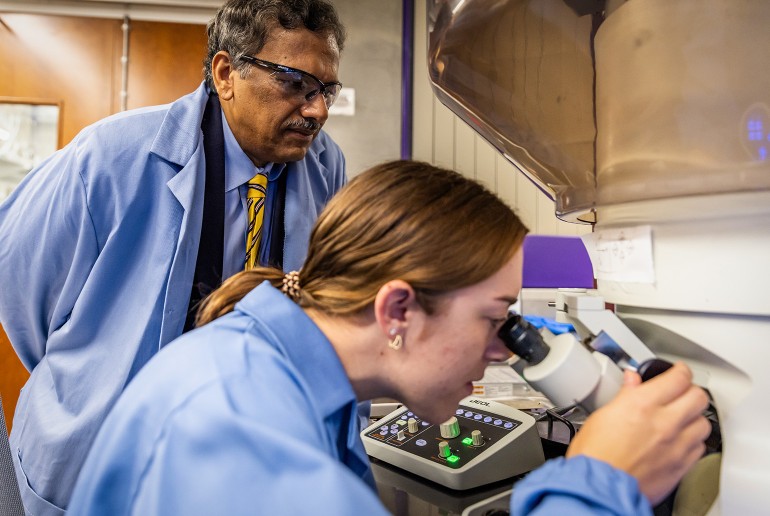

“The technology can be used as a universal sorbent or ‘catch-all,’ or it can be tailored to certain groups of contaminants like metals, plastics or nutrients,” said principal investigator Vinayak Dravid.

Dravid is the Abraham Harris Professor of Materials Science and Engineering at Northwestern’s McCormick School of Engineering and a faculty affiliate of the Paula M. Trienens Institute for Sustainability and Energy. He is also the founding director of the Northwestern University Atomic and Nanoscale Characterization (NUANCE) Center as well as the Soft and Hybrid Nanotechnology Experimental (SHyNE) Resource, and also serves as the associate director for global programs at the International Institute of Nanotechnology.

Like a Swiss Army knife

In its first iteration, the sponge platform was made of polyurethane and coated with a substance that attracted oil and repelled water. The newest version is a highly hydrophilic (water-loving) cellulose sponge coated with particles tailored to other pollutants. The sponge platform works so effectively because of its pores, providing lots of surface area where pollutants can attach.

Dravid has at times referred to the technology as a “Swiss Army knife” thanks to its versatility and ability to be used again and again. He co-founded NU startup Coral Innovations (formerly MFNS-Tech) to begin the process of commercializing the sponge-based technology for environmental remediation.