In the race to make solar energy more practical amidst soaring gas prices and threats of climate catastrophe, a team of researchers is taking steps toward a more efficient, higher-voltage solar cell.

Now, a Northwestern University, University of Toronto and the University of Toledo team is introducing in a new type of solar cell produced without silicon. Not only does the new cell have extremely high efficiency and record-setting voltage, it also bypasses the need for silicon, which is energetically costly to produce and purify.

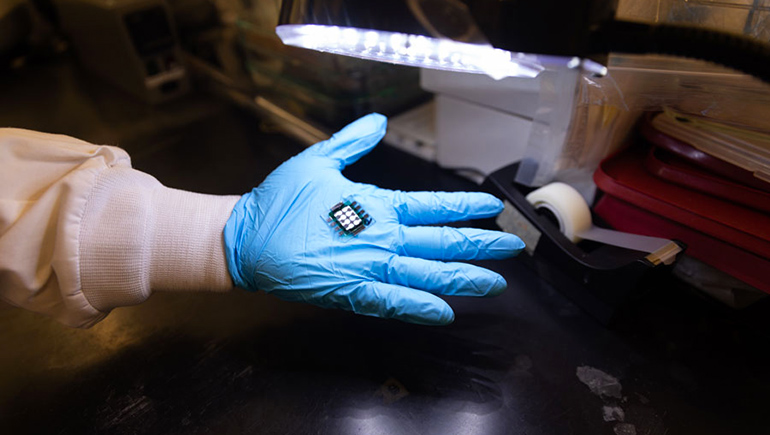

In a new paper published this week in Nature, the international team of researchers used two different layers of perovskites — a type of nanocrystal dispersed in a liquid and coated onto a surface using low-cost, well-established techniques. The researchers then tuned each perovskite layer to a different part of the solar spectrum, producing a tandem solar cell.

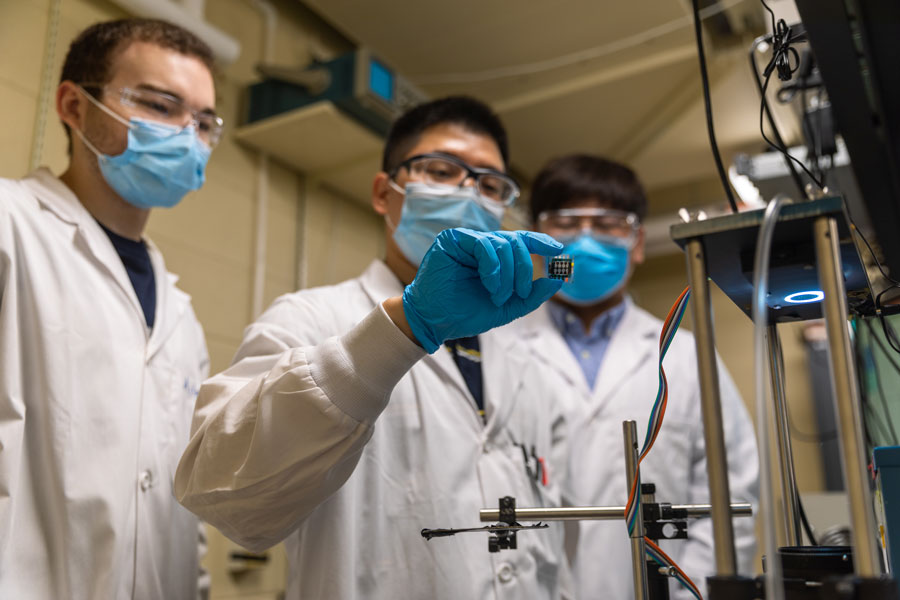

The team’s prototype solar cell measures one square centimeter in area and produces an open-circuit voltage of 2.19 electron volts, a record for all-perovskite tandem solar cells. Its power-conversion efficiency reached 27.4%, which also breaks the current record for traditional silicon solar cells.

“Further improvements in the efficiency of solar cells are crucial for the ongoing decarbonization of our economy,” said corresponding author Ted Sargent. “While silicon solar cells have undergone impressive advances in recent years, there are inherent limitations to their efficiency and cost, arising from material properties. Perovskite technology can overcome these limitations, but, until now, it had performed below its full potential. Our latest study identifies a key reason for this and points a way forward.”

Sargent joined Northwestern this fall as the Lynn Hopton Davis and Greg Davis Professor of Chemistry at the Weinberg College of Arts and Sciences and a professor of electrical and computer engineering in the McCormick School of Engineering.

By adjusting the thickness and chemical composition of the perovskite crystal films, manufacturers can selectively “tune” which wavelengths of light are absorbed and converted into electricity. This is a beneficial contrast to silicon, which always absorbs the same limited section of the solar spectrum.

“In our cell, the top perovskite layer absorbs well in the ultraviolet part of the spectrum, as well as some visible light,” said Chongwen Li, a postdoctoral researcher in Sargent’s lab and one of five co-first authors of the new paper. “The bottom layer has a narrow band gap, which is tuned more toward the infrared part of the spectrum. Between the two, we cover more of the spectrum than would be possible with silicon.”