When spiders spin their webs, they use their hind legs to pull silk threads from their spinnerets. This pulling action doesn’t just help the spider release the silk, it’s also a crucial step in strengthening the silk fibers for a more durable web.

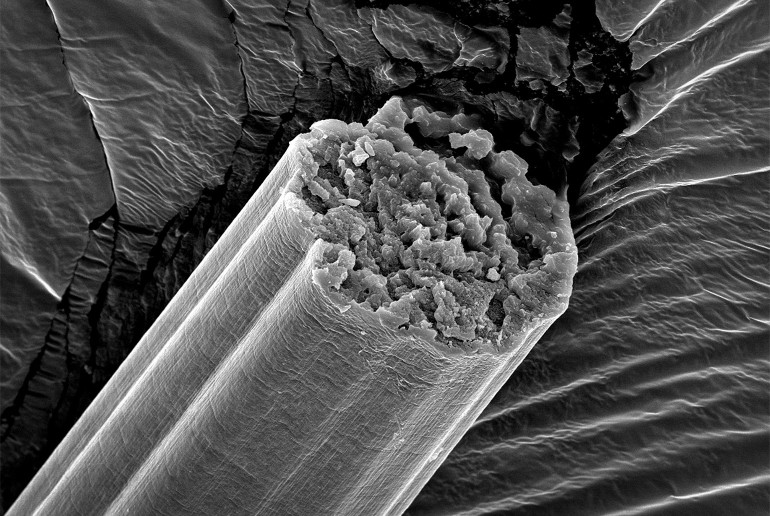

In a new study, Northwestern University researchers have discovered why the role of stretching is so important. By simulating spider silk in a computational model, the team discovered the stretching process aligns the protein chains within the fibers and increases the number of bonds between those chains. Both factors lead to stronger, tougher fibers.

The team then validated these computational predictions through laboratory experiments using engineered spider silk. These insights could help researchers design engineered silk-inspired proteins and spinning processes for various applications, including strong, biodegradable sutures and tough, high-performance, blast-proof body armor.

I definitely look at spiders in a new light.”

“Researchers already knew this stretching, or drawing, is necessary for making really strong fibers,” said Northwestern’s Sinan Keten, the study’s senior author. “But no one necessarily knew why. With our computational method, we were able to probe what’s happening at the nanoscale to gain insights that cannot be seen experimentally. We could examine how drawing relates to the silk’s mechanical properties.”

“Spiders perform the drawing process naturally,” said Northwestern’s Jacob Graham, the study’s first author. “When they spin silk out of their silk gland, spiders use their hind legs to grab the fiber and pull it out. That stretches the fiber as it’s being formed. It makes the fiber very strong and very elastic. We found that you can modify the fiber’s mechanical properties simply through modifying the amount of stretching.”

An expert in bioinspired materials, Keten is the Jerome B. Cohen Professor of Engineering, professor and associate chair of mechanical engineering and professor of civil and environmental engineering at Northwestern’s McCormick School of Engineering. Graham is a Ph.D. student in Keten’s research group.